Vapor control Solutions for

Oil refineries and

petrochemical refineries

Spike Enterprise Inc. provides the following Vapor Control Solutions:

Air Scrubbing Systems • Flare Units • Thermal Oxidizers • Carbon Canister Systems

Spike Enterprise has been performing vapor control solutions, along with odor and emission controls since 1994.

By teaming up with the leaders in the industry and offering multiple solutions, Spike Enterprise Inc. can ensure that the needs of our clients meet all local, state, and federal regulations.

We make sure our clients’ emission controls needs are handled safely and professionally.

DOWNLOAD OUR VAPOR SOLUTIONS BROCHURE

AIR SCRUBBING SYSTEMS

ABOUT OUR AIR SCRUBBING SYSTEMS

The Spike Enterprise Inc. Countercurrent Spray Column Absorber is designed to reduce volatile organic emissions especially where the VOCs are soluble. Spike scrubbing towers maximize absorption of VOCs through the use of proper up-front modeling and design request from the client.

The Spike Air Scrubbing tower has two critical components to the design and operation of the tower. The first component, is the design of the tower and the use of water as a soluble solution. The second component is the use of chemicals to aid in the destruction and/or solubility of the VOCs.

OUR AIR SCRUBBING SYSTEMS ARE ENGINEERED TO MAZIMIZE ABSORPTION

| FAN TYPE | FLOW | ACTUAL FLOW |

|---|---|---|

| Coppus Fan #1 | 11,000 CFM | 5,500 CFM |

| Coppus Fan #2 | 11,000 CFM | 5,500 CFM |

| Super Sucker of GapVac | 3,000 CFM | 2,400 CFM |

| Total Volume | 25,000 CFM | 13,400 CFM |

Notes:

- To account for the volume drop of air along a 20-inch duct for 50 to 250 feet, the gas volume was multiplied by a correction factor of 20 to 50%.

- Inlet and outlet ports are also available for testing the effectiveness of the column.

SPIKE ENTERPRISE AIR SCRUBBER SYSTEM DETAILS

DIMENSIONS

The Spike Enterprise Countercurrent Spray Column Absorber consists of a seven-foot diameter shell that stands 22 feet tall with a four-foot diameter 6-foot tall stack resting on top.

VAPOR CONDENSER

The top two feet of the vessel are equipped with a condenser to prevent vapors from exiting the column with exhaust air. To increase the efficiency of the condenser, a hollow spray nozzle is positioned above the incoming mist to increase particle size before entering the condenser.

AIR-ATOMIZING NOZZLES

To maximize the rate of absorption, the Spike Countercurrent Spray Column Absorber is equipped with three air-atomizing nozzles located 15 feet from the bottom of the column. These nozzles disperse the solvent as a fine mist, thereby increasing the surface area and speeding diffusion.

SOLVENT RESERVOIR

The bottom three feet of the vessel contain a reservoir for the solvent. The column has the ability to recycle the solvent until it becomes saturated with the solute, in most cases BTEX components. The total volume of the reservoir is 840 gallons.

GAS INLETS

The Column is equipped with three gas inlet points located 3.5 feet from the bottom of the column. Two inlets have 20-inch internal diameters and the remaining inlet is 10 inches in internal diameter. The two larger inlets accept gaseous vapors from storage tanks using Coppus ventilation fans. The smaller inlet handles lower volume sources such as vacuum trucks.

AIR SCRUBBING SYSTEMS SIMULATIONS

RESULTS

A simulation using Excel spreadsheets determines the abilities and limitations of the Spike Countercurrent Spray Column Absorber.

INPUT VALUES

Simulations using water as a solvent were used to test the effectiveness of the Spike Column. The table to the right shows the given concentrations and flow rates used in the simulation.

| INPUT | RATE |

|---|---|

| Gaseous Vapor Flow Rate (varies) | 3,000 to 20,000 scfm |

| Emulsion Flow Rate | 2000 gpm |

| Benzene (98%) | 2900 ppm |

| Toluene (95%) | 7600 ppm |

| Ethyl Benzene (95%) | 2600 ppm |

| Xylene (95%) | 9800 ppm |

| Solvent Flow Rate into Scrubber | 200 gpm |

| Percentage of Solvent Recycled | 40% |

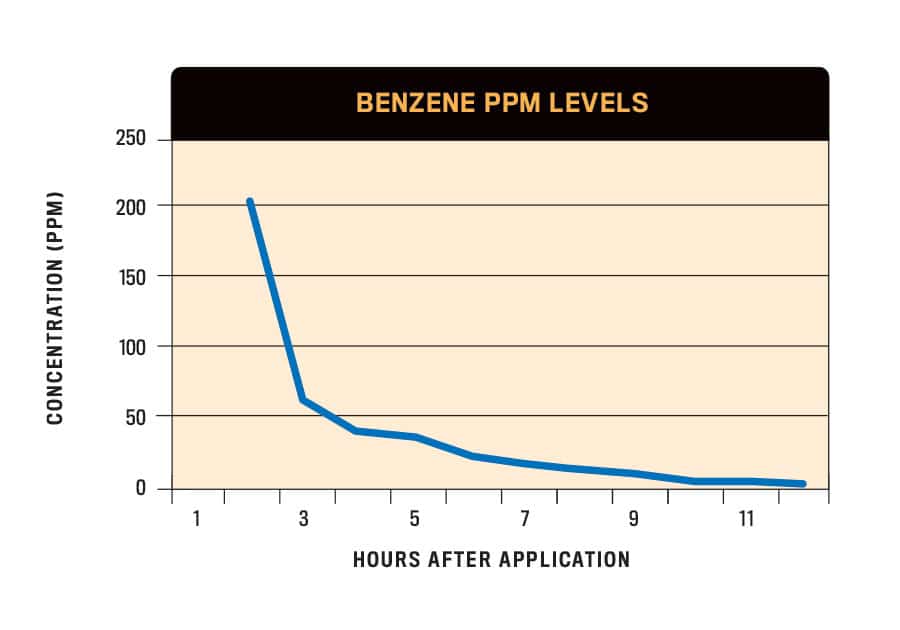

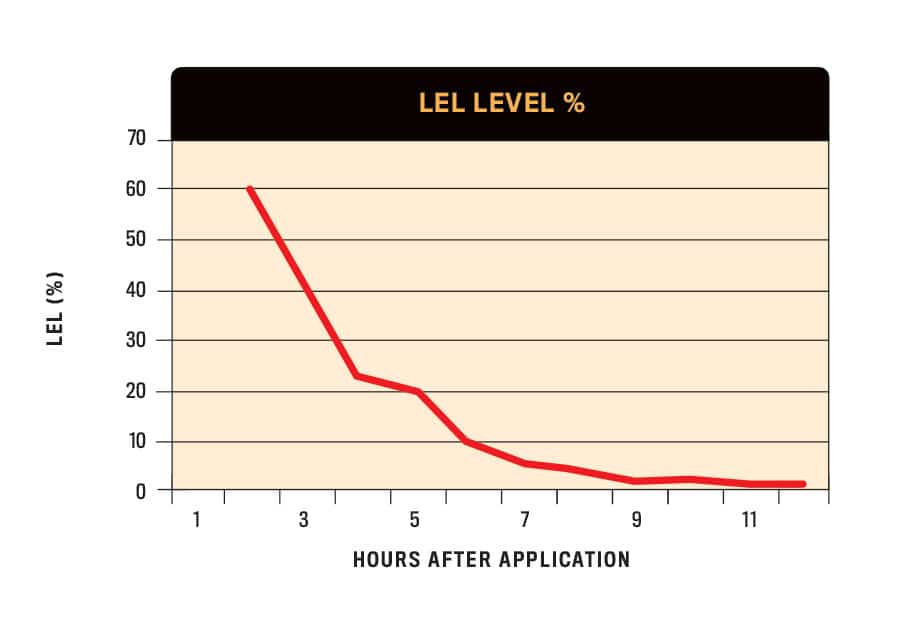

AIR SCRUBBING SYSTEMS GRAPHICAL ANALYSIS

Graphical analysis charts of these simulations are included in the following charts.

Click charts to enlarge.

WATER AS SOLVENT SIMULATION #1

Percentage of BTEX removed with 3,000 scfm gas and 200 gpm water.

A slight increase in removal, and benzene achieves 98% removal while recycling less than 30%.

WATER AS SOLVENT SIMULATION #2

Percentage of BTEX removed with 10,000 scfm gas and 200 gpm water.

All components except benzene meet their treatment criteria. A gas flow rate of 10,000 scfm is not recommended unless carbon is used for final treatment of exhaust gases.

WATER AS SOLVENT SIMULATION #3

Percentage of BTEX removed with 20,000 scfm gas and 200gpm water.

All components except benzene meet their treatment criteria. A gas flow rate of 20,000 scfm is not recommended unless carbon is used for final treatment of exhaust gases.

CHEMICAL AS SOLVENT SOLUTION

There are many different types of chemicals that may be used in our scrubbing system.

Whether needing to scrub Hydrocarbons, Hydrogen Sulfides, Amines, H2S, Benzene, or a variety of other components, Spike Enterprise has the capability of determining the right chemical media for the right solution.

ADVANTAGES OF MECHANICAL PLUS CHEMICAL TECHNOLOGIES

The Spike Air Scrubbing system, otherwise known as The Countercurrent Spray Column Absorber, is achieved through two different components. The first being the mechanical design of the equipment and the second is the targeted chemical applied to the process.

When the mechanical and chemical technologies are combined, we can dramatically increase the efficiency of our scrubbing process.

The major result is a dramatic reduction in the cost compared to Carbon Systems, Flare Units, and Thermal Oxidizers.

ADVANTAGES OF MECHANICAL PLUS CHEMICAL TECHNOLOGIES

The Spike Air Scrubbing system, otherwise known as The Countercurrent Spray Column Absorber, is achieved through two different components. The first being the mechanical design of the equipment and the second is the targeted chemical applied to the process.

When the mechanical and chemical technologies are combined, we can dramatically increase the efficiency of our scrubbing process.

The major result is a dramatic reduction in the cost compared to Carbon Systems, Flare Units, and Thermal Oxidizers.

FLARE UNITS

ABOUT OUR FLARE UNITS

Some situations call for a temporary flare system. A mobile flare system or unit, collects and discharges gas from atmospheric or pressurized tanks and/or vessels and channels them to a safe location for a controlled burn of the vapors. Flare systems typically have a pilot or ignition device that ignites the gas exiting the system.

EFFICIENCY

VOC destruction efficiency depends upon an adequate flame temperature and residence time in the combustion zone. A properly operated flare can achieve a destruction efficiency of 98% as long as the heat content is equal to or greater than 11 megajoules per standard cubic meter or 300 British thermal units per standard cubic foot.

Spike Enterprise Inc. works closely with a variety of companies to help design and operate these unique units to help aid in our clients’ vapor control needs.

THERMAL OXIDIZERS

WHAT IS A THERMAL OXIDIZER?

A Thermal Oxidizer is a mobile degassing unit used to destroy hazardous air pollutants (HAP’s) and volatile organic compounds (VOC’s) from industrial air streams. These pollutants are generally hydrocarbon based. When destroyed through thermal combustion they are chemically oxidized to produce H2O and CO2. Thermal Oxidizers operate around 1,400 degrees F, making them the optimal solution for achieving total vapor control while keeping hazardous vapors from entering the atmosphere.

COST EFFECTIVE SOLUTIONS

We have teamed up with the leading experts in the industry to offer the largest fleet and range of Thermal Oxidizers with a burner capacity ranging from 1.5 MMBTU to 70 MMBTU. This partnership allows us to provide our clients with the appropriate equipment and most cost effective solution for every job.

CARBON CANISTER SYSTEMS

ABOUT OUR CARBON CANISTER SYSTEMS

The Spike Enterprise Inc. Carbon Canister Systems utilize carbon and other absorption media to provide high VOC removal. These systems can remove up to 99% of VOC if needed.

These carbon absorption systems are typically smaller and basic in design to handle emissions with lower concentration of VOCs or other design requirements.

OUR DUAL CARBON CANISTER SYSTEM SPECS

- Skid Size: 4’ x 8’

- Canister Size: 36” Dia. x 60” Tall, (2)

- Carbon Capacity: 21 cubic feet per side approximately 600 lbs of carbon per side.

- Blower Size: 600 CFM @ 3500 RPM

- Power Required: 3phase/ 480 volt/ 5hp

- Input Volume: Keep to 550 CFM or less.

- Loading Carbon: Remove 36” top and load. Remove from canister same way.

DOWNLOAD OUR VAPOR CONTROL SOLUTIONS BROCHURE

Get the pdf version of our latest Vapor Control Solutions brochure.